How is Malbec Wine Made Step by Step

Have you ever wondered how Malbec wine is made? The winemaking process is long and complex, where a trained team is needed to perform each task. But in this article we’re going to explain it clearly so you can understand it easily.

Table of Contents

Harvesting, first step in Malbec making process

The manual harvest begins very early, to avoid high temperatures. The first container where the grapes are gathered is a plastic container. Once the plastic bin is full, it is dumped into the plastic boxes that are placed on the sides of the alley. Here a first harvested grape selection is made. The harvesters then remove any leaf that may have fallen during the harvest. Once this is done, the grapes are transported from the vineyard to the winery.

Destemming

Once entered the winery, each plastic box with grapes is dumped on the bunch selection belt. Here all those that don’t meet quality standards are discarded.

Then, the grapes fall into the destemmer, a machine that is responsible for separating the grains from the skeleton of the bunch called “stalk”. Now, the grains, already separated from the stalk, go through a second selection process on a vibrating table. So, all those that are broken or defective are discarded.

Crushing

After destemming, the process continues with the crushing of the grapes. What does this mean? The crushing consists of causing the breaking of the skins and the detachment of the pulp. This facilitates the exit of the juice without breaking the solid parts. In other words, this is the moment when the grains are broken to start extracting the grape juice.

Many years ago, this task was carried out with bare feet. This was known as grape-treading or grape stomping. This is a hallmark of the traditional harvest since it was a key element in the winemaking process of the first viticulturists. Now it is done in modern machines that allow the juice to be released. And they cause the least damage possible without breaking the seeds.

Sometimes, winemakers use machines that do both destemmer and crushing. These machines are known as crusher-destemmer. So, they are used to separate the grapes themselves from the stems. And then, they split open the grape to get the juice inside that is going to be fermented. In the following video, you can see winemakers using a grape crusher destemmer.

Alcoholic Fermentation

The grape that has passed the careful selection, is transported to the concrete pool using a pump and special pipe. Once the grapes enter the concrete pools, the fermentation process begins. Here the natural sugar turns into alcohol thanks to the work of the yeasts.

During this stage, winemakers do the reassembly. This is a process that is done during fermentation. In the case of red grape juice, the goal is to help extract components found in the grape skin.

In this process, winemakers extract the liquid from the bottom of the tank using a pump. And they inject this liquid through a series of sprinklers on the cap. Their goal is to mix the liquid with the skins and seeds that float during fermentation. In addition, reassembly helps the extraction of colour found in the skin of the grape. On the other hand, winemakers do this to aerate and homogenize the fermenting grape juice.

How often is this done? The grape juice is tasted and analyzed daily and that is where they decide when to do it. Initially, a vat can have two daily reassemblies. But as the days go by and fermentation progresses, these are done less frequently.

At the process end, it’s obtained a liquid known as “free-run juice”. This product is used to make the highest quality wine.

Pressing

But after fermentation, solid remains still contain a large amount of juice. So, winemakers apply pressure to grapes to separate juice or wine from grapes and grape skins. The liquid obtained by pressing is known as “press juice”. This product will be used to make wine of less quality than what is made with “free-run juice”. Pressed juice is much more astringent than free-run juice because it has more tannins.

Often winemakers will keep free-run and pressed juice separated for most of the winemaking process including malolactic fermentation and barrel ageing. Later, they may choose to blend between them to make the most complete and balanced wine. So, they add free run juice to pressed juice to reduce its tannins. On the other hand, they may bottle them separately under different labels and price tiers or discard/sell off the pressed fractions to another producer.

Malolactic fermentation

Through this process, malic acid, one of the 3 acids present in wine along with tartaric and citric, is converted into lactic acid. This process reduces the acid character of the wine and makes it much more pleasant for drinking.

Both the pressed juice and free-run juice go through malolactic fermentation but always separately. They’re never mixed with each other since they are destined for the elaboration of different products.

Ageing of Malbec wine

After the two fermentations, one of the main steps in winemaking is the ageing process. The wine obtained during the previous steps is placed in oak barrels. The wood for the production of barrels is selected mainly for its hardness, permeability and porosity.

This wood is treated with heat to give it shape and when it comes into contact with the fire, the interior of the barrels will present different degrees of toasting. Both the type of oak used, the degree of toasting, and the number of times the barrels have been used will modify the character of the wine.

During the ageing in oak barrels, the wine acquires aromatic notes that we can identify as toasted, smoked, vanilla and woody. So, a series of physical-chemical processes take place. And at the same time, the porosity of the wood also allows micro-oxygenation of the wine. With this, the wine will evolve and develop its characteristics.

This step is optional. Not all wines are ageing. Among some reasons, storage is expensive. So, it´s not profitable to age cheap wines. Besides, not all wines improve their quality after the ageing process.

Clarification and stabilization of Malbec wine

At the end of fermentation, the yeasts and lactic acid bacteria die and break down, releasing the components of the cell interior into the environment. Most fall to the bottom of the tank. But some components are so small and light that they remain suspended. This makes the wine cloudy and unstable. These components, small proteins, tannins and sugars that the yeast doesn’t know how to transform into alcohol, could cause olfactory or taste problems such as bitterness or astringency. For the wine to be stable, clean and bright, as we find it in the bottle, a clarification is necessary.

What is the clarification process?

Clarification consists of incorporating substances capable of agglutinating all these floating compounds so that they weigh more and fall to the bottom of the tank. In this way, we manage to clean the wine, stabilize it and improve its filtration before bottling. The organoleptic qualities of the wine are also preserved and improved.

How the clarification is carried out?

Milk, egg whites and fish glue were already used as fining agents in the 17th century, and their use spread to quality wines in the 18th century. In the 19th century, it became a systematic practice for all types of wines. In those days, it was done disproportionately so that the wine was clean as soon as possible to sell it to the countries of northern Europe. From 1980, the clarification began to be done in a softer, more reasoned way, preserving the quality of the wine to the maximum.

Today there are countless different clarifying agents to obtain the best results. The winemaker decides the type and dose depending on the wine. Also, he keeps in mind the result he wants to obtain and the price. To give you an idea, they can be of animal origin (whey, egg white, gelatin, fish glue), vegetable (pea, potato or algae proteins), mineral (bentonite) or synthetic.

Its use it’s very simple. The winemakers dilute the clarifying agent, introduce it into the tank according to the recommended dose, mix well and let it fall to the bottom. After a while, all you have to do is remove the “clean” wine, which will be almost ready for bottling. Of course, all these products don’t leave any residue or flavour in the wine.

Bottling

Bottling is the last phase of the winemaking process. It consists of introducing the wine into the bottles and applying the corresponding closure. Some of these bottles will hit the market immediately. But others, such as ageing or reserve wines, must remain at rest for a time before being marketed.

In Argentina, there are also small companies that make handcraft Malbec. So, here is an interesting video about that (English subtitles).

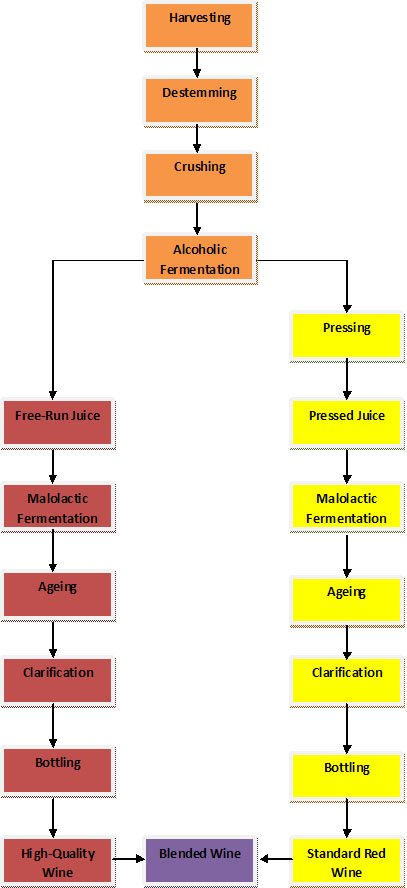

Summary

The following flow chart summarizes how Malbec wine is made. I hope it will be helpful for you.